Seam-Sealed Construction

There have been tremendous advancements in waterproof fabrics in recent years—fabrics that not only lock out water, but are more breathable, comfortable, and durable than previous materials. However, even the world’s most advanced waterproof fabrics still have two fatal weaknesses: the scissor and the needle.

When a roll of fabric is cut into patterns, pieced to form a design, and then sewn together to create a jacket, its technical properties can become compromised. Every stitch requires a tiny needle hole to be punched through the fabric, creating thousands of points where moisture can enter. So while a jacket may boast that it is made of waterproof fabric, the jacket itself may not be waterproof at all—unless special care was taken during its construction.

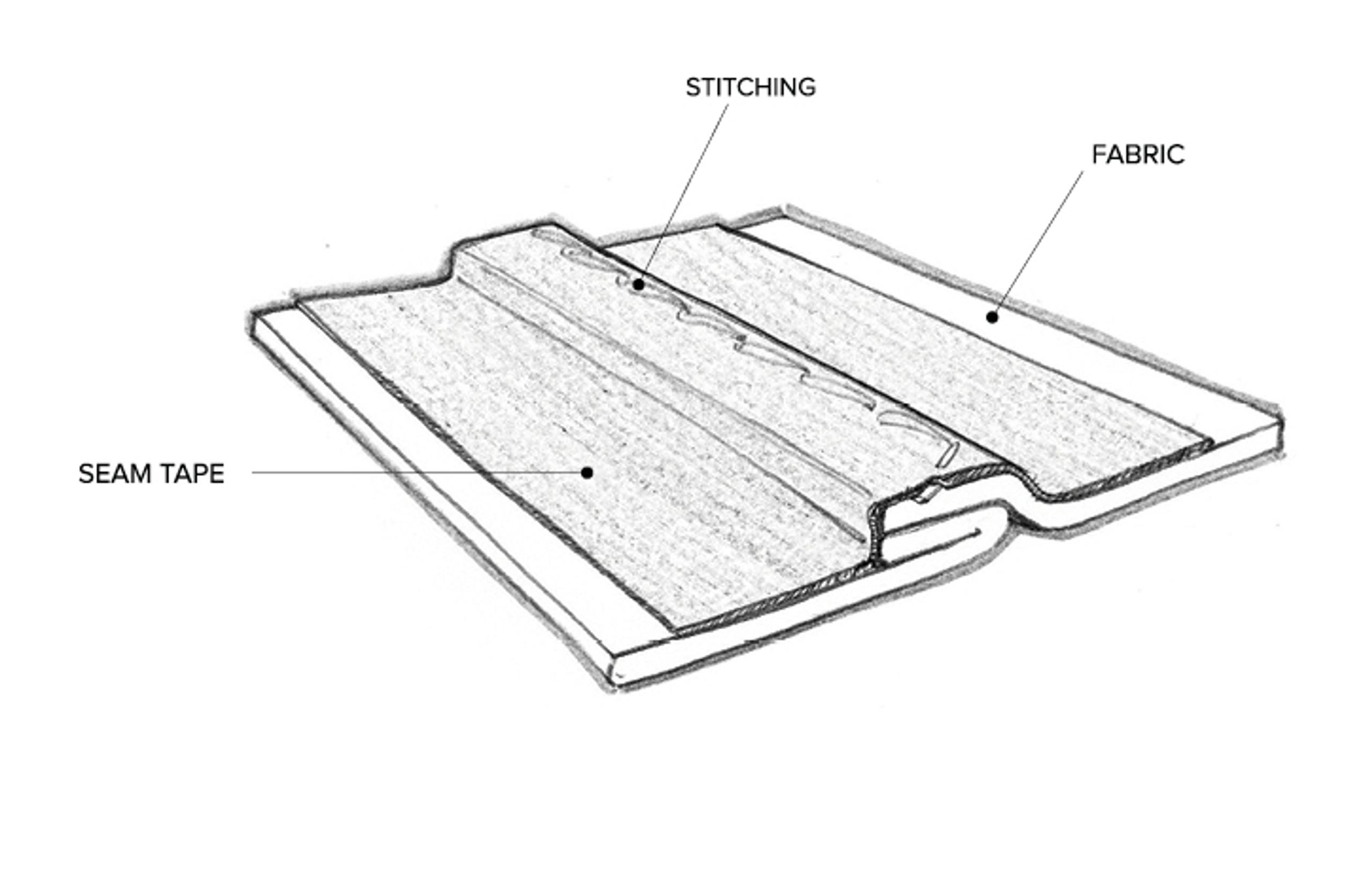

Seam sealing is a process used in garment construction where thin strips of adhesive tape are applied along the length of a seam to prevent water from seeping through. Here, the standard needle-and-thread seam provides the necessary tensile strength to hold the fabric together, and the sticky back of the adhesive tape provides the waterproof sealing.

So the next time you are purchasing a garment that you need to be truly waterproof, make sure to check if its seams have been sealed during construction.

Gale: ($425) - A modern raincoat with a sophisticated silhouette, the Gale has been designed to handle everything from a drizzle to a deluge.

Cascade: ($485) - Whether it’s a light sprinkle or torrential downpour, the Cascade was designed to keep you dry and comfortable when the skies begin to darken.